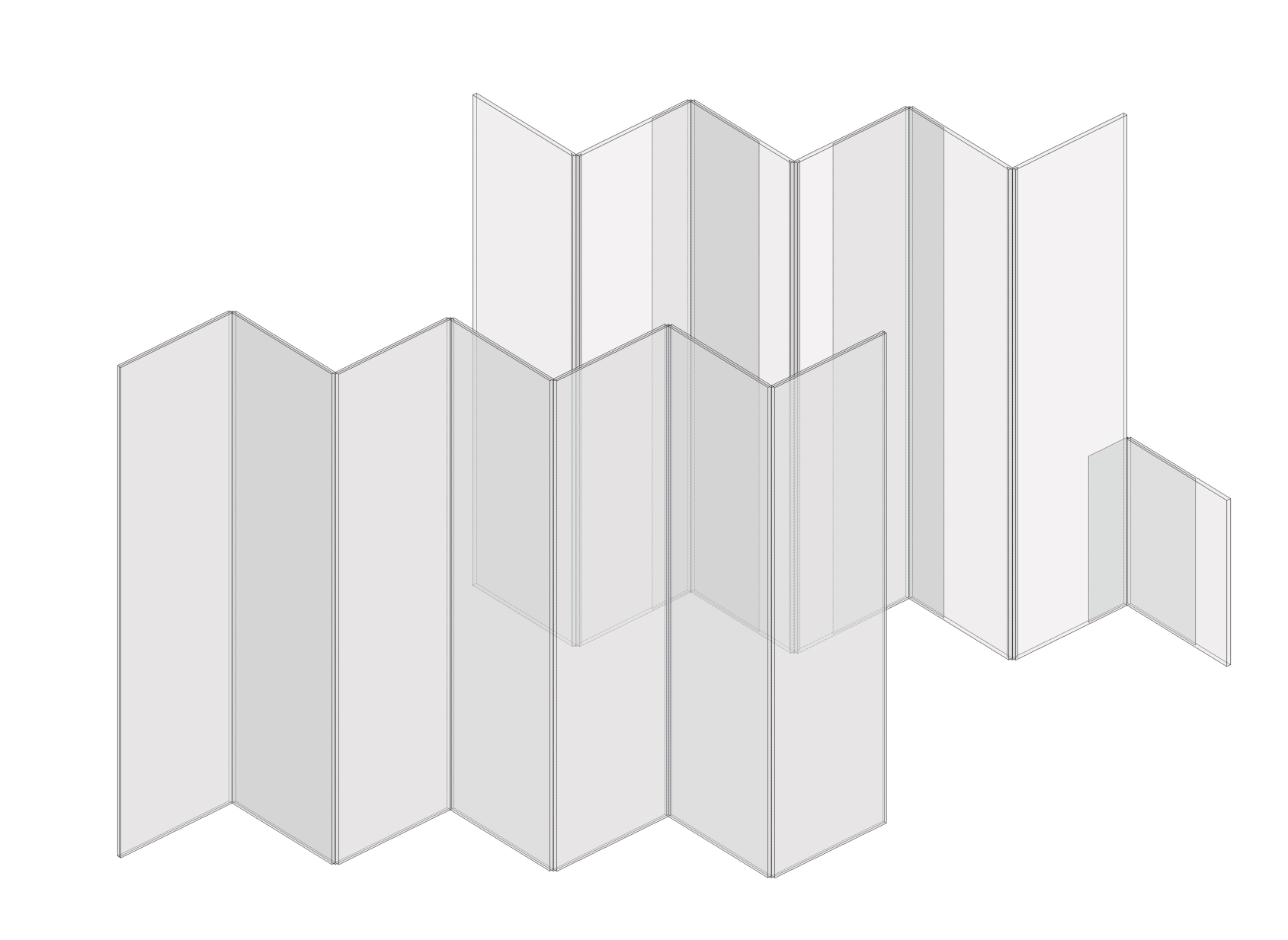

The prototype of the folded reinforced glass was built for the International Conference on Structures and Architecture 2013 held at the University of Minho in Guimarães. The chosen site is located on the east side of the Azurém Campus, flanked by the main entrance hall and the main auditorium. It is a rectangular shaped garden, measuring 20 m x 5 m covered with grass in all its extent. Besides the strategic location, this specific site was chosen for the possibility to cover the auxiliary structure and achieve a more dramatic display of the system.

The prototype is composed of two parallel glass walls with folded geometry. Each composed by seven individual plates connected with the investigated technic. All the individual plates measure 2950 mm x 735 mm, with the exception of the first, which measures only 1053 mm high to reveal the detail. The total comprises 14 panels defining an area of 5,5 m long and 2,6 m width. Each individual plate is composed of: fully tempered glass (2 x 12 mm), Sentryglas® foils (3 x 0,89 mm), stainless steel perforated plate (1,2mm) (In certain panels where the steel perforated plate cover the whole area, only two Sentryglas® foils were used).

One of the walls is fully "reinforced", exhibiting glass panels with perforated sheets in its entire surface, while the other exhibits a freer arrangement, alternating zones with and without reinforcement. The purpose is to clearly show the flexibility of the system when designing the purpose of connection. The ability to drastically reduce the amount of embedded perforated plate is tolerable by the excellent behaviour of the adhesive mechanism studied during the experimental investigation. The fact that the polycarbonate bar of the joint presents a reduced width of only 16 mm, exhibits a polished surface and recessed in relation to the glass plane, contributes to the desire optical fading of the joint. In the traditional systems, it is there where the emphasis happens, which prevents a subtle definition of the planes that compose it.

At the end, the system delivers a specific aesthetic deriving from its essence, in other words, what materializes is also what reinforces and structurally connects. The different materials that compose it are characterized by a certain degree of transparency that once superimposed, offer a complex game of different degrees of transparencies. By changing the angle of observation and lighting conditions, the solution shows its architectural pregnancy. The folded geometry ensures high inertia, allowing it to be self-supporting both in façades and roofs.

Industrial Partners:

Textile membranes are usually used to cover big spans with complex geometries, using the special properties of the Hypar (Hyperbolic paraboloide). However it is possible to use membranes on small external façades and coverings, with low spans, not only as sandwich panels, but also as a junction of small Hypar modules. Like this the mechanical special properties of this geometry can be well explored, allowing a very small weight and thus a good environ-mental performance, compared to conventional façade and covering solutions, on a comparable thickness.

Apart from this, the research on membrane materials for thermal regulation, allows to extend its possibilities in order to fulfill contemporary demands of comfort. In the outer skin, architectural membranes can be used as passive systems, for heating (promoting greenhouse effect) and cooling (shading or even evaporative cooling), as well as allowing some transparency, and thus also natural lighting, specially important on south and north facades.

The CUBE Membrane Test Cell prototype was made in 2010 on the Azurém Campus of the University of Minho, and has been adapted several times to evaluate different research concepts of external membrane façade systems and lightweight and mixedweight inertia building concepts.

|

ADjustMEMBRANE: Innovative Lightweight Adjustable Partition Wall System

|

The permanent evolution and mutation of life styles have been conducting to the rethink of living spaces and to a growing need for more evolutionary and adaptable housing units. It can be verified that a major portion of houses don’t accomplish that premise.

This happens because the technological and constructive solutions used on conventional interior partition walls, such as hollow brick or plasterboard with metallic frame systems, are static and difficult to readapt without a significant cost due to the specialized work required and material loss during the assembly process.

The proposed conceptual system, called ADjustMEMBRANE constitute a modular building solution of a non-load bearing partition wall, tensioned between the pavement and ceiling slabs, that are used as anchoring elements.

It allows several advantages related with the weight reduction to achieve a good sustainable performance, such as: reduce costs on energy, materials and construction; easy recycling, reusing and allow self-construction.